Drive and control

Industrial high-speed doors

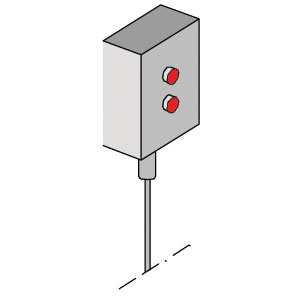

The CS 310 control unit allows easy system control and is standard.

In the event of a power failure or power failure, the drive can be operated manually using a hand lever or chain.

In the basic version, the door can be opened with a button on one side. In practice, due to the purpose of the door, the so-called. fast passage, different door operation management options have been developed, depending on the needs of the clients, the applied internal transport technology inside the hall, and the wishes of the customer. Here are the following additional ways to control the door:

Suitable for installation on the other side of the door, for pedestrian entry-exit. An up-stop-down key is available, as well as a locked key, up-stop-down-key.

The most common way of control for forklift drivers. The set consists of a universal receiver two-channel D343, type Marantec, and transmitter D304 / D302

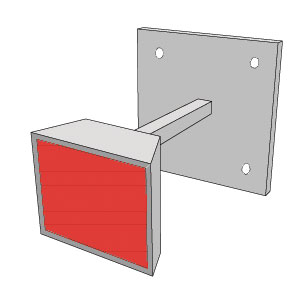

A control mode that provides different models of automatic door control depending on the needs of the user. The device detects movement in front of the door, and sends a signal to open it. After passing, the door closes automatically.

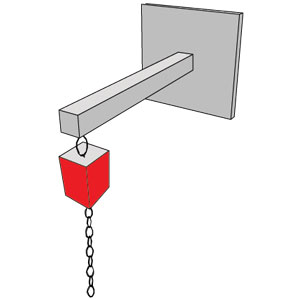

Pulling the chain activates the switch. This method is suitable for pedestrians and forklift drivers, where the triggering is done from a greater distance, up to 1.5 m. The set contains a microswitch on the move and a console for carrying it

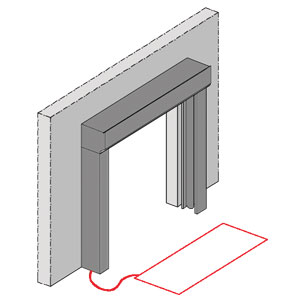

A method that is intended exclusively for forklift drivers, because it does not react to pedestrians. It is installed in the floor (concrete), in previously excavated small grooves of channels, in which an inductive loop (cable) is placed, which detects metal objects (vehicles), and sends a signal to the door opening command. Closing automatically.